3D printing is an excellent technique to progress quickly from design to prototype. Parts designed in CAD can be printed with minimal additional effort. No part-specific tooling such as molds or fixtures is required. This allows parts to be made cheaply and quickly. 3D printing holds the following advantages over other manufacturing methods:

Cost

Good 3D prints can be made on inexpensive machines, and the filament is usually also quite cheap. This results in cheap parts, which frees you to try out more options without breaking the bank.

Speed

We can deliver 3D printed parts quickly, usually sending them out within 24 hours. This leaves you with more time for innovating, or returns your machines to service faster.

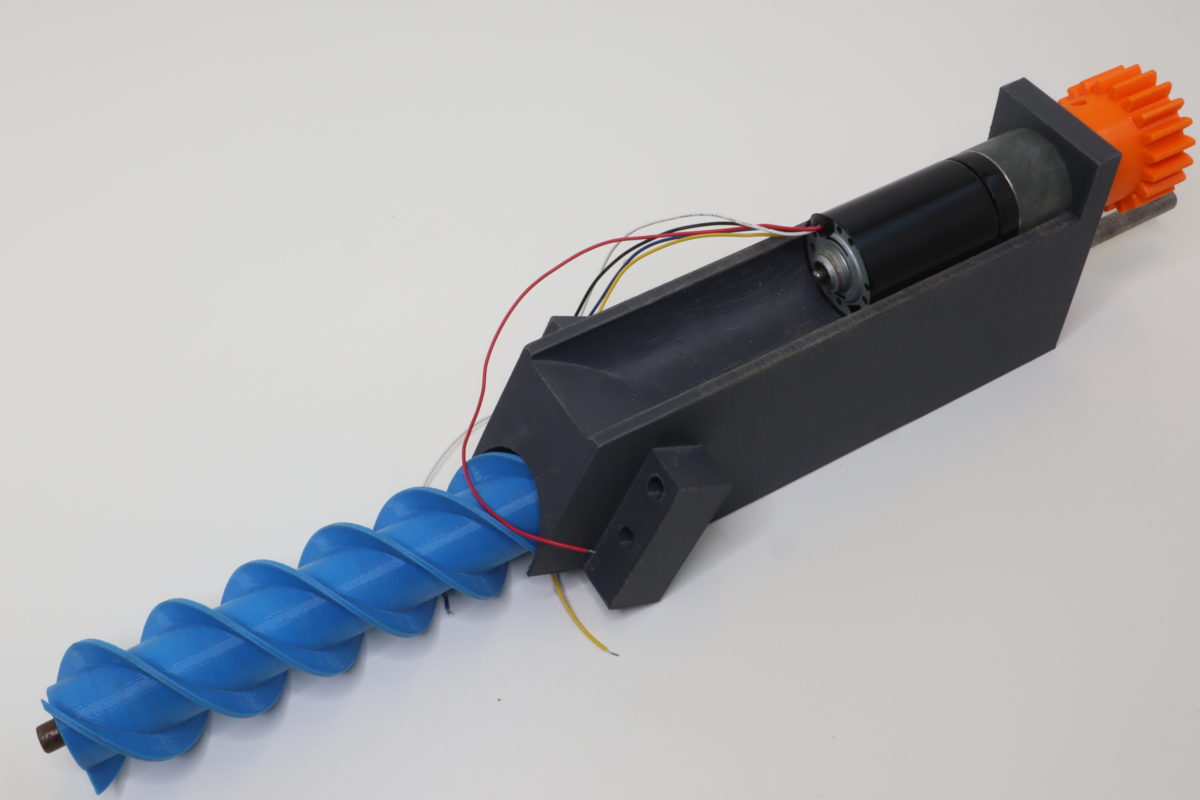

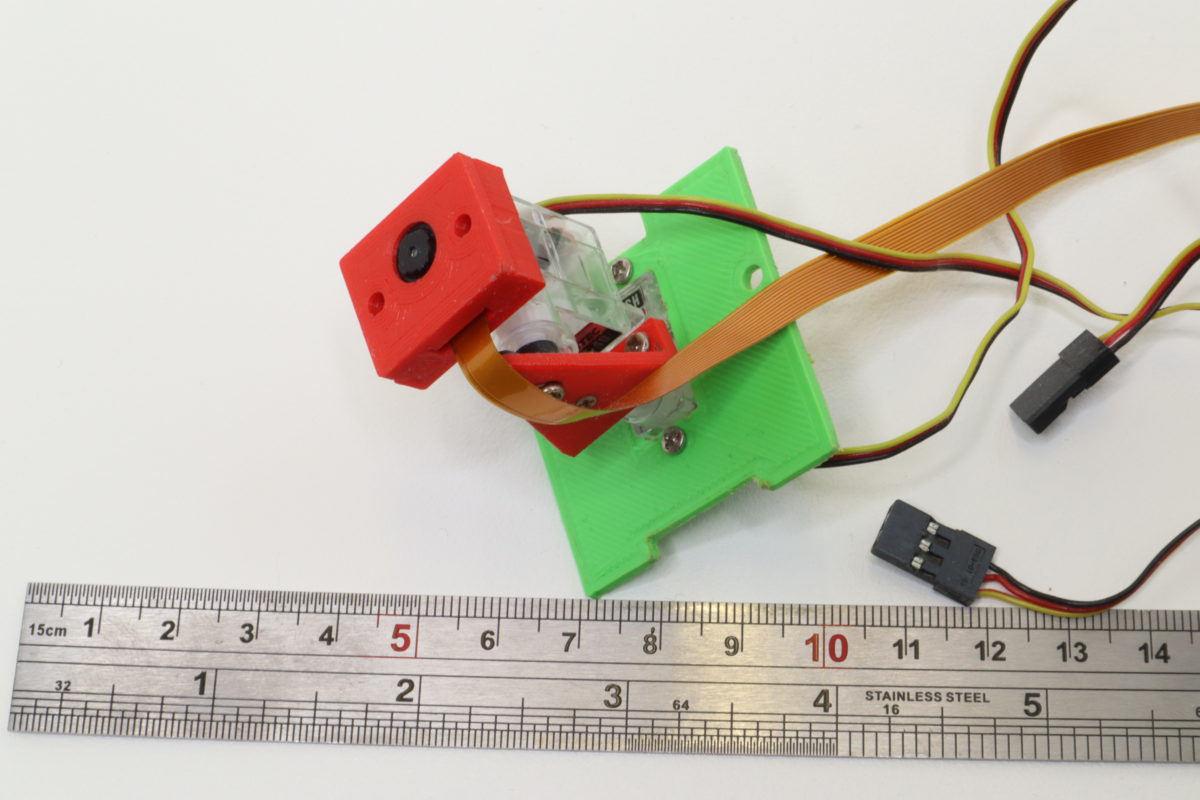

Complex geometry

3D printing allows you to make complex and intricate geometries easily. Re-entrant features are extremely difficult or impossible to make using moulding or CNC machining, even on a 5-axis machine. A 3D printer has no problem creating such geometry.

Weight and stiffness

The interior of 3D printed parts is not solid material, like it would be with traditional manufacturing methods. Instead it consists of a lattice structure called “infill”. This ensures that for example 70% of the interior is air, while only 30% of the space is taken up by plastic. The exact ratio can be freely selected. This retains most of the strength and stiffness of a solid part, but reduces the weight and cost of the part significantly. This ability is unique to additive manufacturing methods.